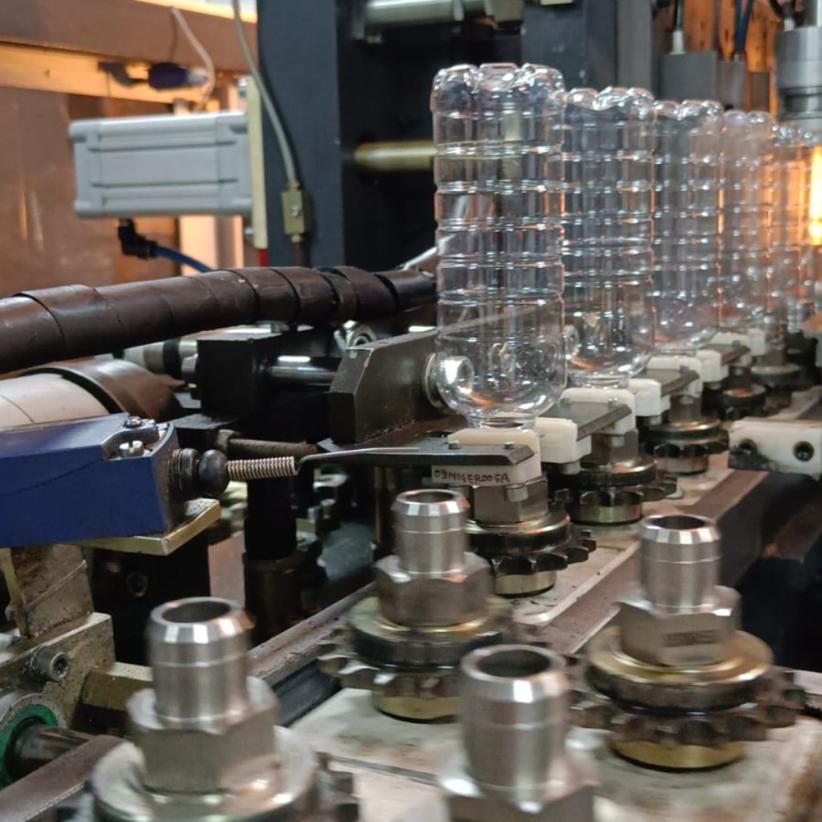

Khetawat Beverages Pvt Ltd holds ISO and ISI certifications and boasts experienced directors, including Mr. Dinesh Khetawat, with 30 years of manufacturing and trading expertise, and Mr. Hitesh Khetawat, a skilled IIT graduate. Their fully automated plant operates at 150 BPM, capable of producing 200,000 bottles daily in various sizes. Committed to delivering clean, bacteria-free water with a pH of 7.5+, the company follows strict compliance with BIS and FSSAI norms. Emphasizing employee well-being, they offer extensive facilities and foster a cohesive team culture. Their vision is to be a top beverages brand, ensuring premium-quality water and expanding into other beverages.

Khetawat Beverages embraces sustainability through eco-conscious operations. They prioritize reducing their footprint via energy-efficient machinery, water optimization, and eco-packaging. Investing in renewables and recycling programs, they drive sustainability across their value chain, ensuring an environmentally responsible future while delivering quality products.

- Renewable Energy

- Eco-Friendly Packaging

- Water Conservation

- Recycling Programs

- Energy Efficiency

- Waste Reduction

Professional Team

Pradeep

Managing director

Pradeep

Blowing operator

Ramesh

Label operator

Kailash

Blowing operator

Dalpat

Accountant

Chetan

Technical head

Devendra

Filler operator

Sugreev

Microbiologist

Testimonials

Pre-Ozonation

Sand Gravity Filtration

This critical step ensures meticulous removal of minute particles, preserving sensitive equipment in later stages and preventing fouling, ensuring the process’s smooth progression.

Activated Carbon Filtration

Employed to eradicate chlorine, pesticides, herbicides, and a range of organic contaminants. Additionally, it serves to trap larger particles, averting equipment clogging, and enhancing subsequent filtration efficiency.

Multigrade Filtration

Imperative at the initial phase to eliminate larger particles, safeguarding sensitive equipment against fouling, ensuring sustained operational efficiency.

Reverse Osmosis

TDS Enhancement & Mineral Dosing

This critical step ensures meticulous removal of minute particles, preserving sensitive equipment in later stages and preventing fouling, ensuring the process’s smooth progression.

5-Micron Cartridge Filtration

Executes a thorough filtration process, eliminating minute impurities of up to 0.45 microns, thereby ensuring unparalleled water purity and quality. Simultaneously, it preserves the sealed conditions within the bottle.

Final Ozonation

Concludes the process by meticulously eliminating even the tiniest micron-level particles from the water, guaranteeing the maintenance of the bottle’s sealed condition.

Why choose us?

Sturdy Bottles

Initiates with raw water collection followed by aeration to eliminate odors, CO2, heavy metals (lead, iron, mercury, cadmium), and microbial load reduction through ozonation. Sand gravity filtration effectively eliminates 98-99% of microorganisms and impurities.

Size and Quality

Our 500ml bottle equals or exceeds the weight of other companies’ 1L bottles, providing added durability and attractiveness.

Enhanced Offerings

Providing a 250ml bottle at the price of a 200ml bottle, ensuring superior quality and value for customers.

Water Treatment

Our water undergoes ozonation, silverization, and an 8-step quality process, maintaining a pH value of 7.5+ while eliminating harmful substances.

Sourced Raw Water

Directly sourced from a dam with a TDS value below 450, undergoing further filtration for purity.

Location Advantage

Situated away from GIDC areas to avoid potential borewell contaminants, maintaining a TDS value lower than 1500.

Stringent Testing

Daily, weekly, and monthly tests uphold taste, color, essential properties, and microbial load within BIS standards.

Quality Assurance

Samples tested for shelf life and rigorous checks on labeling, date coding, bottle, and cap conditions before market dispatch ensure consistent quality.